Fujitsu VR-II Heat Recovery System 22.4kW – 135kW

Key Features

- System Outline

- High Operating Energy Efficiency

- Energy saving technology that boosted operation efficiency

- Ideal heat exchanger path control

- Sophisticated operation control

- Flexible piping connection

- Flexible installation of RB unit

Download Leaflet

Simultaneous Cooling & Heating Operation Using 1 Refrigerant System

Cooling and heating can be freely selected for each indoor unit to provide simultaneous cooling and heating in the rooms with large temperature differences, etc.

Annual Cooling Operation

Use annual cooling operation for the rooms and other spaces that require constant temperature control throughout the year.

Handles Changes in the Temperature Difference

The operation mode can be freely changed when there are large temperature differences during the day, such as between seasons.

Intelligent Refrigerant Control

Fujitsu General proposes New outdoor unit which includes New refrigerant control.

New refrigerant control can be operated with suitable control corresponding to heat load of the room and can offer a more comfortable space. New refrigerant control can also provide more energy savings.

* The improvement by the control and the actual sine wave varies by the combination of the indoor unit and system operating condition.

Improvement In The Number Of Connectable Indoor Units

Connectable indoor unit capacity range

New model (VR-IV) : 25%* to 150%

Current model (VR-II) : 50% to 150%

* For modular type, 25% to 49.9% operation in the entire system is available. (by one unit operation)

Connectable indoor unit number Space Saving Combination

Energy Saving Technology That Boosted Operation Efficiency

Powerful Large Propeller Fan

By using CFD*1 technology, a newly designed fan achieves high performance and low noise operation.

-

*1. CFD = Computational Fluid Dynamics

3 Phase DC Fan Motor

Efficiency is substantially improved by high efficient motor with sophisticated driver control. In addition, low noise is realized by DC fan motor.

Sine-wave DC Inverter Control

High efficiency is realised by adoption of reduced switching loss IPM.

4-face Heat Exchanger

Heat exchange efficiency is significantly improved by the introduction of a new 4-face heat exchanger that increases effective surface area.

Subcool heat exchanger

High Heat Exchange efficiency is achieved by using an internal projection shape double pipe construction.

Highly efficient & Large Capacity DC Inverter Compressor

Large capacity high efficient DC twin rotary compressor with excellent intermediate capability.

Front Intake Port (corner cut air inhaling structure)

In multiple outdoor unit installations, the unique front intake design improves airflow into the Heat Exchanger.

Extended Connection Ratio (for Multi-tenant application)

This function is especially effective when partial air-conditioning starts at the building under construction. Installation work can be added flexibly for each tenant.

Current model (VR-II) Example) for 12HP: 6HP operations for 50% are required.

50%

Current model (VR-II) Example) for 12HP: 6HP operations for 50% are required.

25%

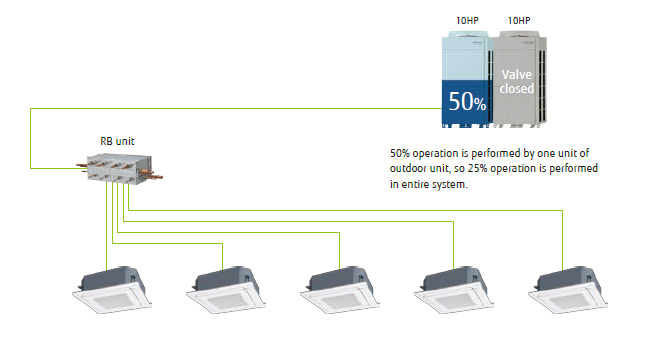

Modular Type

One outdoor unit operates effectively for the connectable indoor unit capacity in the entire system. (25% operation by multiple units is not available.)

Example) for 25% operation (5HP) of 20HP (10HP x 2 units) 5HP operation by 50% of one 10HP outdoor unit is performed. →25% operation by 2 units is not performed.

Modular Type

Additional Installation Without Changing The Main Pipe

Installation work can be performed from the beginning by the main pipe diameter used in the final system. Unlike current model, changing the main pipe is not necessary, so duplication of work is resolved.

Additional Installation Without Changing The Main Pipe

Efficiency In Actual Operation

Top class high COP(Max. Heating) is achieved for all combinations by our unique heat exchanger structure, high efficient DC twin compressor, and our own technologies.

Space Saving Combination

Energy Efficiency Combination

All Inverter Compressor

Large Capacity DC Inverter Compressor

Large capacity high efficient DC twin rotary compressor with excellent intermediate capability.

Ideal Heat Exchanger Path Control

Heat exchanger is split into top and bottom. Heat exchange efficiency is improved by optimum heat exchanger path refrigerant control. Refrigerant is more distributed at the top side heat exchanger with a large intake airflow.

Sophisticated Operation Control

When multiple outdoor units are connected, sophisticated operation is performed by each compressor. Efficiency is improved by all compressors at part load and distributing refrigerant to all of the heat exchangers rather than to one compressor.

Flexible Piping Connection

A more flexible refrigerant piping work is possible by the use of various piping and RB Unit connections, for adjustments to the floor layout and building structure.

- The RB unit can be freely positioned between the first branch and the indoor unit.

- The maximum height difference between RB units is 15 m.

- 1: RB Unit is not necessary for cooling only use.

Flexible installation of RB unit

- Small & slim design saves space. Hight 198 mm

- A drain pipe is not required

- The control box position can be changed to meet the installation conditions

- Small design saves space

- A drain pipe is not required

- Simple installation series connection design

Installation possible from either side for freedom of the control box

Installation possible on the upper-side for use in narrow space

2-way connection

Up to 2 units can be connected in series.

Easy to Maintain in a Narrow Space

Maintenance can be performed from the side.

Electrics box can be temporarily fixed by sliding down.

Parts can be replaced easily even at narrow space in the ceiling.

Single & Multi Port Options Available

RB unit (single type)

RB unit (multi type)